30/60/100/150/200/300/500/1600 Psi Pressure Sensor Transducer

|

Name |

Current/Voltage Pressure Transmitter |

Shell material |

304 stainless steel |

|

Core category |

Ceramic core, diffused silicon oil-filled core (optional) |

Pressure type |

Gauge pressure type, absolute pressure type or sealed gauge pressure type |

|

Range |

-100kpa...0~20kpa...100MPA (optional) |

Temperature compensation |

-10-70°C |

|

Precision |

0.25%FS, 0.5%FS, 1%FS (comprehensive error including non-linear repeatability hysteresis) |

Operating temperature |

-40-125℃ |

|

Safety overload |

2 times full scale pressure |

Limit overload |

3 times full scale pressure |

|

Output |

4~20mADC (two-wire system), 0~10mADC, 0~20mADC, 0~5VDC, 1~5VDC, 0.5-4.5V, 0~10VDC (three-wire system) |

Power supply |

8~32VDC |

|

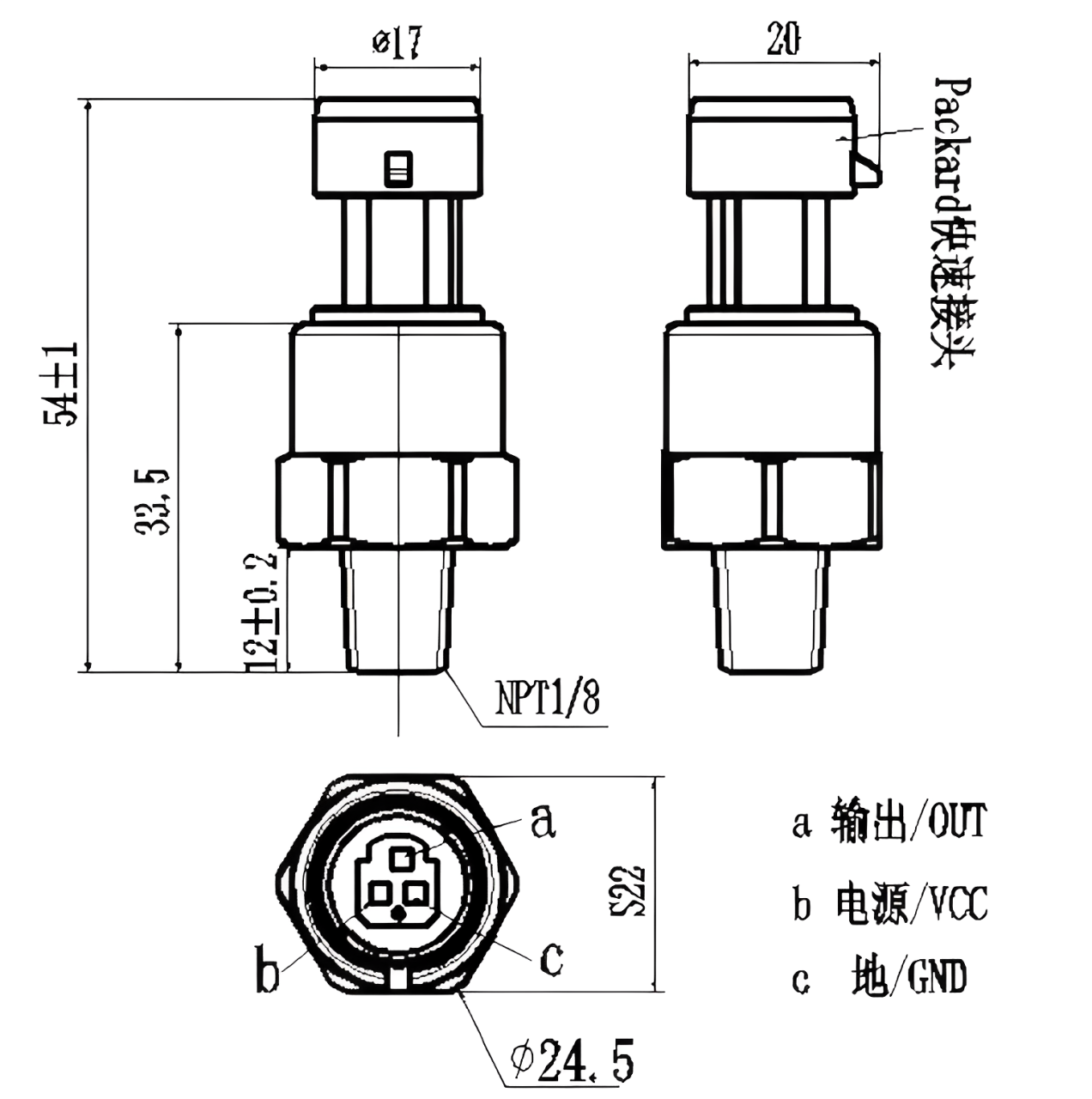

Thread |

NPT1/8 (can be customized) |

Temperature drift |

Zero temperature drift: ≤±0.02%FS℃ Range temperature drift: ≤±0.02%FS℃ |

|

Long-term stability |

0.2%FS/year |

contact material |

304, 316L, fluorine rubber |

|

Electrical connections |

PACK plug, big Hessman, aviation plug, waterproof outlet, M12*1 |

Protection level |

IP65 |

|

Response time (10%~90%) |

≤2ms |

|

The high-precision pressure transmitter is a pressure measurement product developed specifically for applications in the field of high-precision pressure measurement. It is suitable for High-precision measurement of micro pressure。Using internationally advanced pressure sensor manufacturing technology, the product has the characteristics of wide temperature range compensation, small temperature influence, high accuracy, good linearity, good repeatability, low hysteresis, and good long-term stability.Integrated structure, multiple pressure interface forms, multiple electrical connection options, various signal output forms are available, and two forms of gauge pressure and negative pressure are provided. The range can be specified by the user.

Wide pressure measurement range

Wide temperature range

Wide measuring medium range, suitable for various gases, liquids and steam compatible with stainless steel and titanium alloy

All stainless steel structure, Ultra-small structure design to meet the pressure measurement in various narrow spaces

Integrated induction diaphragm, strong anti-vibration and shock ability

Faster dynamic response frequency, captures subtle changes in parameters, and can also reduce the variability of the measurement process

Aviation, aerospace and other experimental equipment

Liquefaction system, various experimental devices

Petroleum, chemical and metallurgical industries

Industrial automation control and detection system

Electric heating, metallurgy, machinery, light industry

Pressure calibration of scientific research institutes, laboratories, etc.

Hydraulic, marine, diesel engine industry

Clean energy, water treatment and building automation

Meteorology, furnace, medical, plastic and glass industry blow molding machines, flow control;

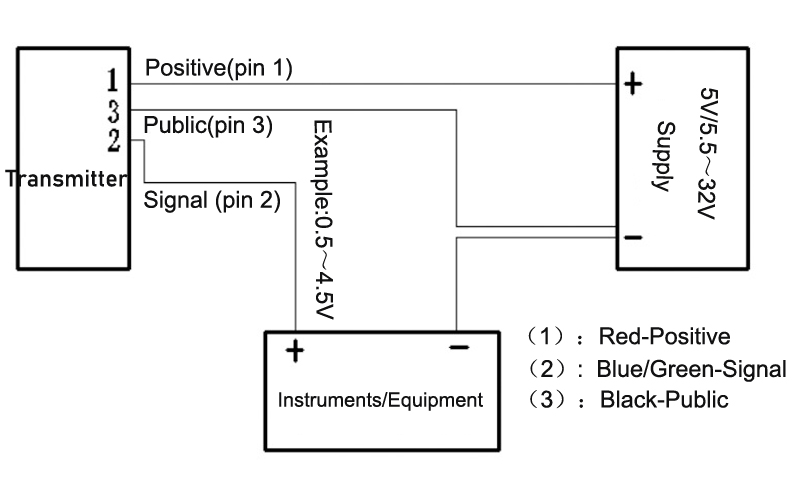

The wiring of the sensor has always been one of the most frequently consulted questions in the procurement process of customers.Many customers don’t know how the sensors are connected. In fact, the wiring methods of various sensors are basically the same.Pressure sensors generally have a two-wire system, a three-wire system, a four-wire system, and some have a five-wire system.

The two-wire system of the pressure sensor is relatively simple, and most customers know how to wire it.One wire is connected to the positive pole of the power supply, and the other wire is the signal wire connected to the negative pole of the power supply through the instrument.The three-wire system of the pressure sensor is based on the two-wire system with a line that is directly connected to the negative pole of the power supply, which is a bit more troublesome than the two-wire system.The four-wire pressure sensor must be two power input terminals, and the other two are signal output terminals.Most of the four-wire system is a voltage output instead of 4-20mA output. The 4-20mA is called a pressure transmitter, and most of them are made into a two-wire system.The signal output of some pressure sensors is not amplified, and the full-scale output is only tens of millivolts, while some pressure sensors have an internal amplification circuit, and the full-scale output is 0~2V.As for how to connect to the display instrument, it depends on the range of the instrument.If there is a gear that is compatible with the output signal, it can be measured directly, otherwise a signal adjustment circuit must be added.The five-wire pressure sensor is not much different from the four-wire system, and there are fewer five-wire sensors on the market.