Featured Products

-

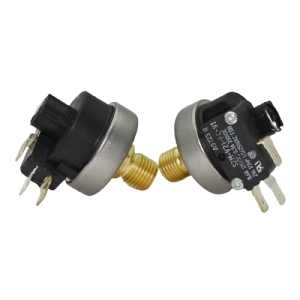

China Factory for China Automatic Pump Control Pressure Switch

The pressure switch adopts stainless steel action diaphragm and is manufactured by mature technology. It has the advantages of fully enclosed, high precision, no drift, small size, vibration resistance, long durability, reliable performance, and convenient installation.It can automatically measure and control the pressure in the system, prevent the pressure in the system from being too high or too low, and output switch signals to ensure that the equipment works within a safe pressure range.

-

One of Hottest for China Electrical Pressure Control Switch

YK series pressure switch (also known as pressure controller) is developed by using special materials, special craftsmanship and learning from the technical advantages of similar products at home and abroad. It is a relatively advanced micro switch in the world.This product has reliable performance and easy installation and use. It is used in heat pumps, oil pumps, air pumps, air-conditioning refrigeration units and other equipment that needs to adjust the pressure of the medium by itself to protect the pressure system.

-

Manufacturer of China Air Ride Compressor Air Tank Pressure Switch

The pressure setting range of this switch is relatively flexible, and it has a wide range of applications. The most common ones are used in various small air pumps, car horns and air compressors.Usually there is a threaded interface, and the switch tail can be welded to the wire. The specification of the wire is according to your requirements, as shown in the figure below

-

Big Discount China Adjustable Steam Pressure Switch for Liquid, Gas

1. Product Name: Water Pressure Switch, Air Pressure Switch, Micro Pressure Switch, Vacuum Switch

2.Electrical parameters: 16 (4) A 250VAC T125 16A 25A 250VAC

3. Applicable medium: steam, air, water, liquid, engine oil, lubricating oil, etc

4.The highest pressure: positive pressure: 1.5MPA; Negative pressure: -101kpa

5. Working temperature: -35℃~160℃ (no frosting)

6. Interface size: conventional G1/8, according to customer requirements

7.Control mode: open and close mode

8. Product material: copper base + plastic shell, or copper base + aluminum shell

9. Mechanical life: 300,000 times

10.Electrical life: 6A 250VAC 100,000 times; 0~16A 250VAC 50,000 times; 16~25A 250VAC 10,000 times

-

Hot Sale for China Manual Reset Pressure Controls Air Compressor Water/Heat Pump Pressure Control Switch

1.Product name: Refrigeration Pressure Switch, Air Compressor Pressure Switch, Steam Pressure Switch, Water Pump Pressure Switch

2. Use medium: refrigerant, gas, liquid, water, oil

3.Electrical parameters: 125V/250V AC 12A

4. Medium temperature: -10~120℃

5. Installation interface; 7/16-20, G1/4, G1/8, M12*1.25, φ6 copper tube, φ2.5mm capillary tube, or customized according to customer requirements

6. Working principle: The switch is normally closed. When the access pressure is greater than the normally closed pressure, the switch is disconnected. When the pressure drops to the reset pressure, the reset is turned on. Realize the control of electrical appliances

-

2022 High quality China Manufacturer Air Mechanical Pressure Switch with High Quality

Electrical parameters : 5(2.5)A 125/250V

Pressure setting: 20pa~5000pa

Applicable pressure: Positive or negative pressure

Contact resistance: ≤50mΩ

Maximum breakage pressure: 10kpa

Operating temperature: -20℃~85℃

Connection size: Diameter 6mm

Insulation resistance: 500V-DC-lasted 1min,≥5MΩ

-

China wholesale China 0.5% Accuracy 0-5V Output Pressure Transducer

The transmitter adopts the international advanced pressure sensing element and transmitter special integrated circuit, which is a high-quality, highly reliable, and anti-overload pressure transmitter.It adopts special pressure chips for refrigeration, air conditioning, and heat pump systems, which are corrosion-resistant, impact-resistant, and have good strong corrosion resistance to refrigerants, which can meet the vibration and impact requirements of refrigeration units, and have stable and reliable performance.Mainly used in water-cooled screw units, ground source heat pumps, refrigerators, ice machines, etc. Its unique anti-condensation design plays a pressure protection role for the safe and efficient operation of the equipment.

-

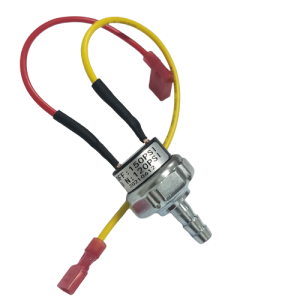

Best Price for China DC12V Air Suspension Pressure Switch for Compressor

This is a pressure switch with a pagoda-shaped joint, and its joint is in a continuous cone shape.So it can better connect with water pipes and air pipes,

This pressure switch is mostly used in small air compressors, small air pumps, and water pumps.Air pipe or water pipe can be installed at its interface, In addition, the inserting part can be connected by soldering wires, and the specified terminal connector can be installed.Of course, if you have high waterproof requirements, you can also add our unique waterproof case, as shown in the figure below

-

CE Certificate China Factory OEM Car Auto AC Refrigerant Pressure Switch

This pressure switch can be used in many fields, such as air conditioning refrigeration systems, car horns, ARB air pumps, air compressors, etc.In the refrigeration and air-conditioning system, the general air-conditioning pressure switch is installed in the air-conditioning condensing pipe, mainly to detect the pressure of the refrigerant in the air-conditioning pipe.When the pressure is abnormal, the corresponding protection circuit is activated to prevent damage to the system.Common air-conditioning pressure switches generally include high-pressure switches, low-pressure switches, two state pressure switches and three state pressure switches.

-

Best Price for China yk Series Automotive Air Conditioning Pressure Sensor with CE

This is an air conditioner three-state pressure switch, which includes a high and low pressure switch and a medium voltage switch. The three-state pressure switch is installed on the high-pressure pipeline of the air-conditioning system.

Low-pressure switch: When the air-conditioning system leaks or the refrigerant is low, in order to protect the compressor from damage, the control circuit of the compressor is forcibly cut off to stop the compressor.

Mid-state switch: When the condensing pressure is high, force the condensing fan to rotate at a high speed to reduce the high pressure pressure and increase the cooling effect.

High pressure switch: In order to prevent the system pressure from being too high, causing the system to explode, the compressor is forced to stop working. When the high-pressure pressure of the air conditioner is abnormally high, the high-pressure switch is opened to cut off the control circuit of the compressor, and the air-conditioning system stops working.

-

Factory Price For China Intelligent Pressure Switch YK Series High Low Pressure Switch

The pressure switch adopts stainless steel action diaphragm and is manufactured by mature technology. It has the advantages of fully enclosed, high precision, no drift, small size, vibration resistance, long durability, reliable performance, and convenient installation.It can automatically measure and control the pressure in the system, prevent the pressure in the system from being too high or too low, and output switch signals to ensure that the equipment works within a safe pressure range.

-

Leading Manufacturer for China Air Ride Suspension Train Horns Bagged Air Compressors pressure switch

The mechanical pressure switch is a micro switch action caused by pure mechanical deformation.When the pressure increases, the different sensing pressure components (diaphragm, bellows, piston) will deform and move upward. The upper micro switch is activated by a mechanical structure such as a railing spring to output an electrical signal. This is the principle of the pressure switch.